Product description

Premium multifunctional cat litter machinery making machine

Product Description of Poultry Feed Processing Machine:

Poultry Feed Processing Machine is specially used to make feed pellet for animals, the feed

pellet is more beneficial to poultry and livestock, and easier to be abosorbed by animal.

Families and small scale farms usually prefer Small Pellet Machine For Feed to make pellet

for raising animals .

Our feed pellet machine can widely used for making poultry ,livestock feed pellets ,including

chicken , pig , sinking fish feed pellets from corn , bean, bran , wheat etc , you also can add

some grass to make some cow , sheep, horse, rabbit feed pellet.

1.WINMI cat litter granulator is an international low-fault model, which is used to produce all

kinds of high quality livestock feed with full price

2.Main drive bearing, oil seal, O-ring and other main standard parts are all imported from

abroad

3.Its appearance, internal design and manufacturing quality are up to the international

advanced level.

4.The main drive adopts high precision gear rotation, and its production is about 15-20%

higher than belt rotation type.

5.The rotating gear adopts precision tooth grinding, vibration absorption, strong isolation

and low noise.

Product specificatio

Matters needing attention

1. During particle processing, it is necessary to check whether there are stones, iron blocks,

metal objects, hard substances and other foreign matters in the raw materials entering the

machine and causing damage to the press roll in the machine.

2. Workers should stand by the machine during granulation to prevent material from springing

out and injuring people during feed processing.

3. Do not touch materials with hands or sticks while the machine is working4. If there is

abnormal sound in the machine, turn off the switch and check it when the machine stops

running.

5. Children, the elderly and those who do not know the performance of the machine and

cannot operate the machine are prohibited to avoid unnecessary troubles.

Cat litter production process

Packing & Delivery

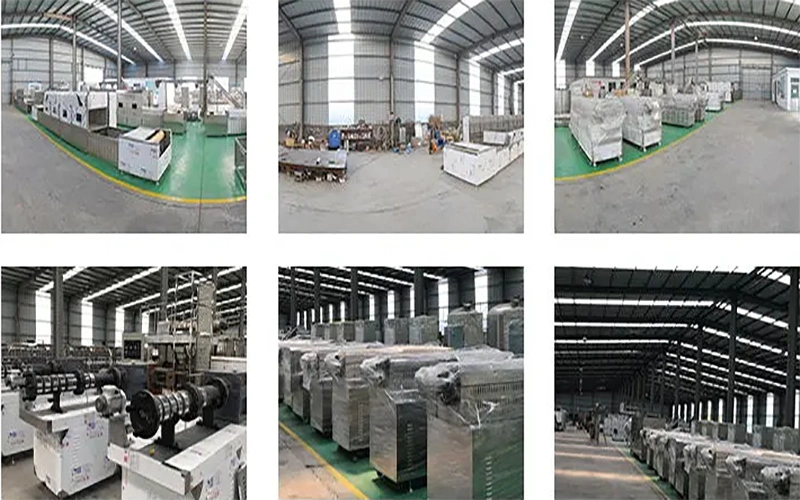

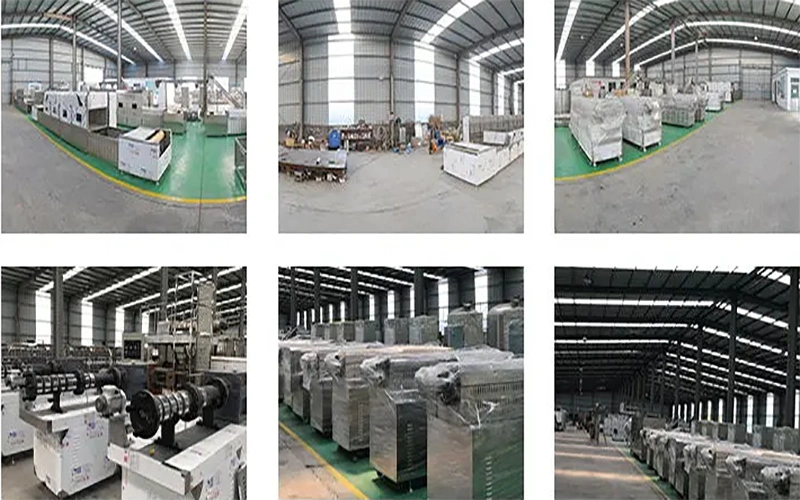

Our factory

Our Service

1.We can provide factory layout according to customer's factory size in advance.

2.When we received your deposit of this order, we will ask our engineers to prepare to apply

the visa, when the equipment arrived your country, and we will send two engineers to go and

help you to install the line, teach your worker(3-4 workers) how to operate the line, until your

worker know the line well.

3.Our engineers has responsibility to teach your worker how to clean the extruder, how to

change the screw, how to change barrel etc. and we have responsibility to provide technology

support with you forever.

4.Our engineers can provide basic formula and help customer to produce good quality food

according customer's detailed formula.

5.The spare parts We provide will at preferential price for an extended long time.

FAQ

Premium multifunctional cat litter machinery making machine

Product Description of Poultry Feed Processing Machine:

Poultry Feed Processing Machine is specially used to make feed pellet for animals, the feed

pellet is more beneficial to poultry and livestock, and easier to be abosorbed by animal.

Families and small scale farms usually prefer Small Pellet Machine For Feed to make pellet

for raising animals .

Our feed pellet machine can widely used for making poultry ,livestock feed pellets ,including

chicken , pig , sinking fish feed pellets from corn , bean, bran , wheat etc , you also can add

some grass to make some cow , sheep, horse, rabbit feed pellet.

1.WINMI cat litter granulator is an international low-fault model, which is used to produce all

kinds of high quality livestock feed with full price

2.Main drive bearing, oil seal, O-ring and other main standard parts are all imported from

abroad

3.Its appearance, internal design and manufacturing quality are up to the international

advanced level.

4.The main drive adopts high precision gear rotation, and its production is about 15-20%

higher than belt rotation type.

5.The rotating gear adopts precision tooth grinding, vibration absorption, strong isolation

and low noise.

Product specificatio

| Product Information | |||||||

| Product Name | premium multifunctional cat litter machinery making machine | ||||||

| Type | 125 | 150 | 210 | 260 | 300 | 400 | 600 |

| Power(KW) | 220V3KW | 220V3KW | 380V7.5KW | 380V15KW | 380V22KW | 380V30KW | 380V55KW |

| Kind of drive | axle | axle | axle | axle | axle | axle | axle |

| Diesel engine | 8 | 8 | 15 | 25 | 40 | 45 | 80 |

| Kind of drive | triangular belt | triangular belt | triangular belt | triangular belt | triangular belt | triangular belt | triangular belt |

| Output(kg/h) | 60-100 | 120-200 | 250-400 | 400-600 | 700-1000 | 1500-2000 | 2500-3500 |

| Rotate speed(r/min) | 320 | 320 | 370 | 370 | 320 | 260 | 260 |

| Boundary dimension(cm) | 0.8*0.3*0.9 | 0.9*0.3*0.9 | 1.1*0.45*1.2 | 1.3*0.5*1.2 | 1.5*0.6.1.4 | 1.6*0.6*1.5 | 2*0.8*1.8 |

1. During particle processing, it is necessary to check whether there are stones, iron blocks,

metal objects, hard substances and other foreign matters in the raw materials entering the

machine and causing damage to the press roll in the machine.

2. Workers should stand by the machine during granulation to prevent material from springing

out and injuring people during feed processing.

3. Do not touch materials with hands or sticks while the machine is working4. If there is

abnormal sound in the machine, turn off the switch and check it when the machine stops

running.

5. Children, the elderly and those who do not know the performance of the machine and

cannot operate the machine are prohibited to avoid unnecessary troubles.

Cat litter production process

Packing & Delivery

Our factory

Our Service

1.We can provide factory layout according to customer's factory size in advance.

2.When we received your deposit of this order, we will ask our engineers to prepare to apply

the visa, when the equipment arrived your country, and we will send two engineers to go and

help you to install the line, teach your worker(3-4 workers) how to operate the line, until your

worker know the line well.

3.Our engineers has responsibility to teach your worker how to clean the extruder, how to

change the screw, how to change barrel etc. and we have responsibility to provide technology

support with you forever.

4.Our engineers can provide basic formula and help customer to produce good quality food

according customer's detailed formula.

5.The spare parts We provide will at preferential price for an extended long time.

FAQ