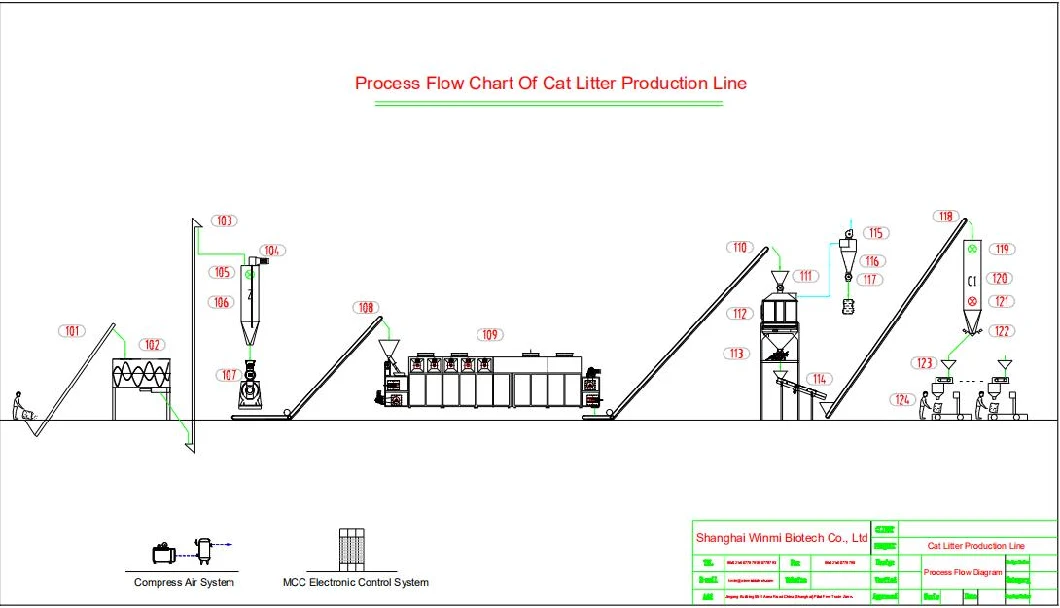

Cat litter product line is composed by many machines,the whole process includes:

mixer - elevator - cone double feeder - single screw granulator - head for hot blowing -

isolating agent addition and recovery system - first stage cyclone separator - second stage

cyclone separator - extended air-cooled vibrating screen - finished product bin.

Here are different type cat litter machine:

1.Tofu cat litter machine

2.Bentontie cat litter machine

3.Crystal silica gel cat litter machine

Depending on your product plan/budget/factory area,we will customize a suitable machine set for you.

For exmaple,customers form ample sunlight countries may don't need dryer machine.

Please feel free to contact us to know more information.

Main Production Section:

1. Mixing Process

In order to mix all kinds of materials after the ingredients, to ensure the quality and effect of the cat litter

particles, the horizontal mixer is used to mix. The mixing efficiency is very fast. It is not easy to block

the material, the mixing is even. The bottom pneumatic door is open, the feed and discharge speed is

very fast.

2. Pelleting Process:(Making Catlitter Pellet Dia 3mm)

Adopt High efficiency Pellet mill,it can produce high quality pellet for,pellet diameter can be 2-8mm.

The raw material of cat litter is granularly shaped, using a highly efficient ring die pellet machine.

The SZLH series of ring die pellet machine is made by our company to absorb the essence of domestic and foreign granulator. The mold is upper and lower two layers, and the pressure roller is made of stainless steel wear-resistant material, with unique design, reasonable structure, long service life and other characteristics. Used extensively in cat litter mills, farms and feed mills, etc.

3. Microwave Drying Process

Microwave drying machine can be widely used in chemical, food, medicine, building materials, electronics, animal breeding and other industries.The material is first pelletized by the pellet mechanism and then evenly spread on the webbing by the automatic spreading device. As the webbing moves forward, the litter particles are dried by the hot air.

4. Pellet Cooling And Sifter Process

Adopt High efficiency Pellet cooler,it can cooler pellet ,use vibrition sifter,then the final product for package.

5. Packing Process

This process is to pack the pellets into bags which is conveninet for storage and transportation.

Investment

Because of the compact structure in the design of these machines, they require small space for they installation.

Low Installing Cost

The Installation procedure of this cat litter plant requires an easy procedure. All the machines are can be utilized immediately after simple installation and connection of the mill parts.

Low Production Cost

This full set of cat litter machine requires only 2-3 workers for once the complete feed production plant is set. The Less labor force implies that less cost is needed in running the plant.This result to a good saving deal which at the end of the day give a size able profit.

Wide Application

STLP300 and STLP400 are designed in such a way that they well for not only cat litter manfuacturing, but also poultry feed manufacturing.

- We can provide factory layout according to customer's factory size in advance.

- When we received your deposit of this order, we will ask our engineers to prepare to apply the visa, when the equipment arrived your country, and we will send two engineers to go and help you to install the line, teach your worker(3-4 workers) how to operate the line, until your worker know the line well.

- Our engineers has responsibility to teach your worker how to clean the extruder, how to change the screw, how to change barrel etc. and we have responsibility to provide technology support with you forever.

- Our engineers can provide basic formula and help customer to produce good quality food according customer's detailed formula.

- The spare parts We provide will at preferential price for an extended long time.

SHANGHAI WINMI BIOTECH CO.,LTD was founded in 2015 by a group of active and innovative young people with the aim that Serving For World and Bringing.Our Product To The Global Gradually. We are willing to assist new customers to grow and regular customers to boost sales.